Air Lubricated Aerodynamic Bearings

For the bearing support of high-speed rotating light shafts and under extreme operating conditions (very low/high temperatures), aerodynamic air bearings represent a solution with a variety of advantages. They are maintenance-free and feature low power loss and long service life.

When lubricating with the ambient air or the gaseous working medium, the contamination of the operating medium, which is inadmissible in many applications (e.g. compressors, cooling turbines), can be avoided. In addition, oil seals can be dispensed with, which considerably simplifies the overall design. This means that other overall designs (encapsulated designs) are possible at all. Foil bearings are a type of air bearing in which a compliant foil structure is used between the rigid bearing housing and the air film. This foil structure serves to improve the adaptability of the bearing to rotor movements and brings with it an external damping mechanism, whereby the bearing remains stable over an extended speed range.

Adaptive Air Foil Bearing: Bearings optimized for a wide range of operating conditions

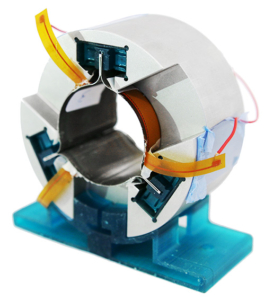

The innovative technology of the adaptive foil bearing was conceived for the first time by the Institute of Adaptronics and Function Integration at the Technical University of Braunschweig and a patent application was filed. In this technology, foil bearings are equipped with an adaptive interface, whereby the effective bearing clearance of the bearing is actively controlled by means of piezoelectric patch actuators and adapted to different operating conditions.

The main objective of the control is to obtain optimum lubrication properties in terms of stiffness and damping behavior at higher speeds and load capacity and effective frictional torques at lower speeds. The result is a bearing in operation that has the optimized characteristics of multiple bearings with different bore geometries in a single bearing. We are pleased to announce that the performance of the adaptive foil bearing has been demonstrated and published based on numerous analyses in theory and the experimental tests with first prototypes.