Click here for more information about our services in the field of rotor bearing systems.

Design with digital calculation tools

We design it for you …

SADAP supports customers on their way to successfully developing air and foil bearings for individual applications. By using high-precision digital design tools, air-lubricated bearings are developed for the machine (e.g. compressors in fuel cells) so that all requirements are met and have optimized properties against the effects that occur during operation. Particular attention is paid to the behavior of the rotor-bearing system under both static and dynamic operating conditions.

Is the development and utilization of air and foil bearings for individual machine concepts of interest to you? More information can be found by clicking here.

Experimental Studies

We measure it for you …

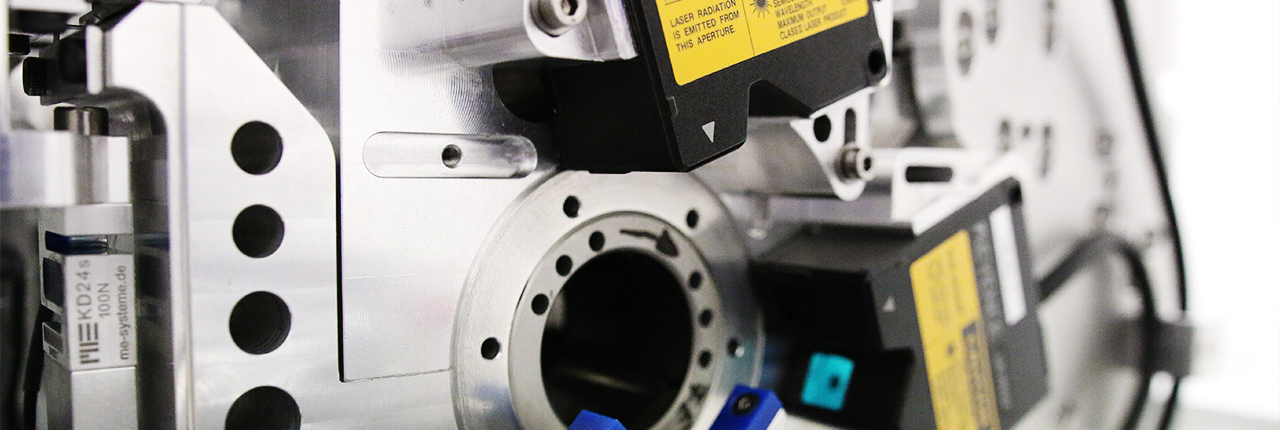

In addition to the design of air and foil bearings, SADAP offers experimental investigations as the next step in a cooperation with the TU Braunschweig. Here, the bearing designed in the first step (as a prototype) is tested and validated in and out of operation.

Experimental studies (out of operation):

The foil bearing consists primarily of compliant foil structures connected in series with the lubrication film to provide stiffness and damping. This additional viscoelastic property keeps the bearing more robust to harmonic and subharmonic shocks and protects the minimum lubrication film thickness from failure.

Based on this consideration, the dynamic properties of the foil structure as a function of the excitation frequency play an essential role. In this respect, SADAP offers a careful investigation of the dynamic behavior of the foil bearings with a focus on film structure and out of service. This type of investigation is called measurement of the mechanical impedance of the foil structure.

The bearing assumed for investigation is harmonically excited in two directions perpendicular to each other (up to 9000 Hz) and the deflection in the respective directions is measured. Post-processing of the measured data determines how the stiffness and damping coefficients of the foil structure react to different frequencies that may occur during operation.

Further information about our services in the form of experimental studies can be found here.

Training offers

We train your team …

Benefit from high-quality knowledge in the direction of optimizing your company’s performance.

- Are you looking for a high-performance training partner?

- Want to train your team at a specific location?

- Or are you planning to have development staff on your team trained in specific areas of expertise?

We offer training services for industrial workers with unique knowledge potential in all areas covered by SADAP. These are mainly training services in the field of rotor dynamics calculation, bearing testing and evaluation of data from experimental investigations and simulation products. But that is not all we would like to offer you. You are welcome to send us your individual request as a corporate customer in the following areas:

- Structural Health Monitoring area

- System identification under mechanical aspects

- Adaptive electromechanical solutions for vibration and noise reduction